Learnings from the World’s Highest-Performing Deposit Return Systems

A series of trends are disrupting recycling and waste management conversations worldwide. The first is a growing awareness that plastic waste is polluting even the far reaches of our planet. Scientists have determined that plastic waste including litter is leaking into the oceans at a rate of a garbage truck per minute, and forecast there will be more plastic in the ocean than fish by 2050 (by weight). This has led researchers to review how much plastic has actually been recycled given current recycling systems in place. Scientists have determined that of all the plastic ever produced, only 9% has been recycled.

The second trend is concerns raised by the Basel Convention and the associated rising costs of collection, processing and recycling for parts of the world that used to rely on China, India, and many other Asian countries to buy and sort through mixed recyclables.

A third trend is a growing aspiration to shift the industrial model away from “take-make-waste” to a “circular economy,” where resources are captured and utilized at their highest material value for as long as possible. This is most evident in the European Union’s Circular Economy Package, which established legally-binding collection and recycling targets for common materials.

Motivated by this confluence of trends, policy-makers, environmental organizations, and businesses are actively evaluating solutions such as a deposit return system (DRS) for the sustainable management of single-use beverage containers. Deposit return systems add a small but meaningful deposit to the sale of each beverage, which is repaid when consumers return the empty containers for recycling. The key elements for a DRS are framed for stakeholders through statute and regulation. The policy is known for its effectiveness, with leading systems routinely recovering in excess of 90% of deposit containers sold. In 2019, the European Union adopted the Single-Use Plastics Directive, mandating that its member states collect 90% of plastic beverage containers by 2029. Experts say this will be difficult to impossible to achieve without a deposit return system in place, and these programs are on the rise.

Between 2017 and 2020, 22 states or countries have committed to updating existing deposit systems or developing new systems. In addition to this group, at least 12 states or countries are currently working on updating existing systems or developing new systems. In 2019, nine US states proposed adopting deposit policies, which is “way more interest than we have seen in the past,” according to the Container Recycling Institute, a non-profit that monitors deposit systems.

TOMRA has over 50 years of experience working in deposit return systems, today working in 40 deposit markets, in every part of the value chain. TOMRA has unique first-hand insights based on its global experience in the field. Now is the right time to understand what makes some programs more successful than others. After analyzing global deposit systems and reflecting on its experience in those markets, TOMRA identified a series of “best practices”.

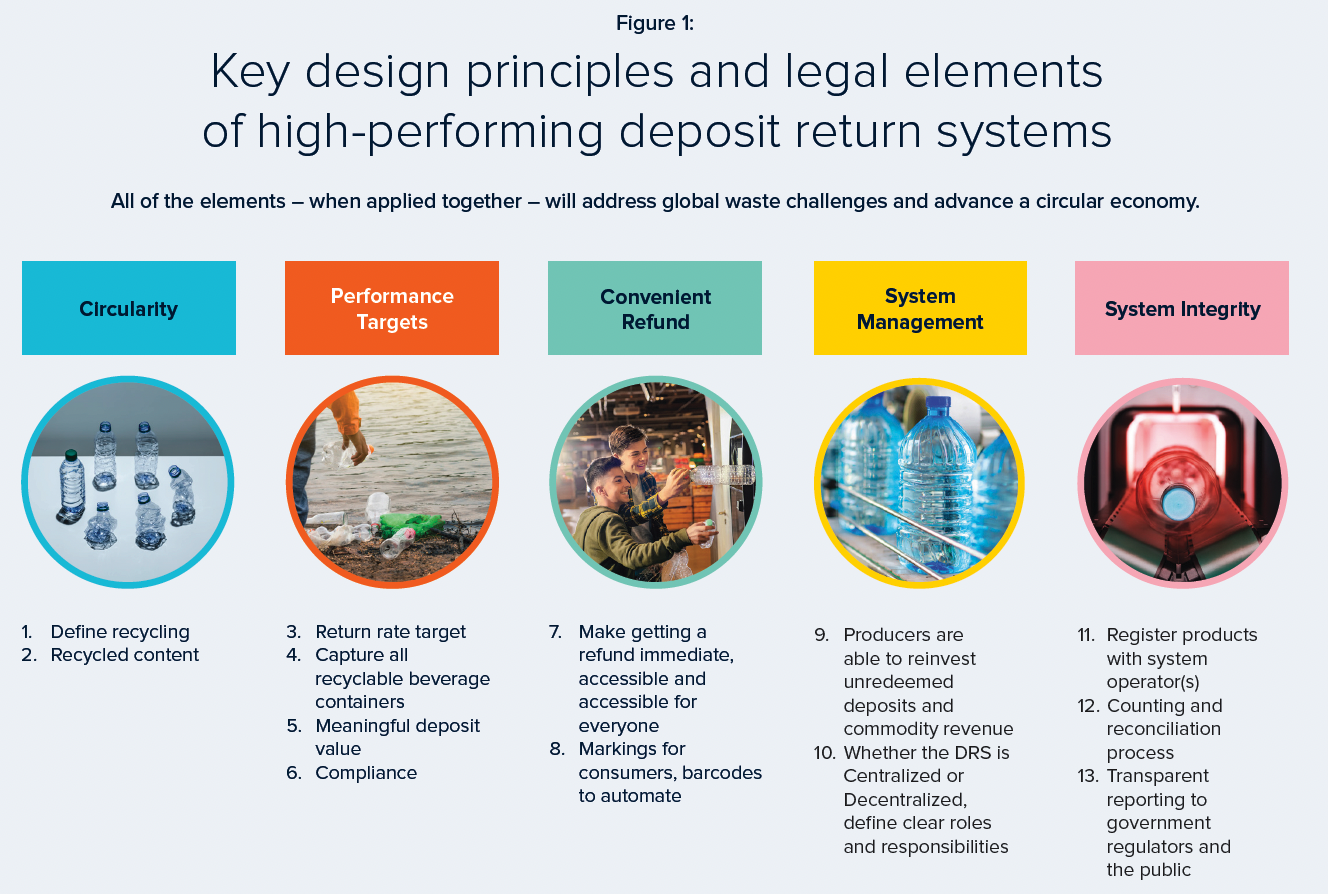

Principles shared among high-performing deposit return systems include:

- Circularity: Financial incentives and penalties exist to ensure containers are effectively recycled not ‘downcycled.’

- Performance Targets: Frame conditions set in statute ensure performance including targets for collection, recycled content and a minimum number of redemption points, plus a meaningful deposit and broad scope.

- Convenient Refund: The redemption system is easy, accessible, and fair for everyone in every neighborhood.

- System Management: Producers finance and manage infrastructure and operations within the frame conditions set by Government; with use of unredeemed deposits and commodity revenues.

- System Integrity: Trust and transparency are built into the system’s processes. Enabled by product registration, data management, a clearinghouse, and redemption specifications.

In practice, these design principles are brought to life through 12 key policy or program elements. All of the elements – when applied together – will address global waste challenges and advance a circular economy. Prioritizing one but not the other will disrupt a deposit system’s performance and cost effectiveness. As with all policies, local culture, infrastructure, and politics need to be factored in to shape the system that works best for each market.

The 12 key elements of high-performing deposit return systems include:

Circularity

- Define recycling

- Recycled content

Performance Targets

- Return rate target

- Capture all recyclable beverage containers

- Set a meaningful deposit value

- Compliance

Convenient Refund

- Make getting a refund immediate, easy, and accessible for everyone

- Markings for consumers, barcodes to automate

System Management

- Producers are able to reinvest unredeemed deposits and commodity revenue

- Whether the DRS is Centralized or Decentralized, define clear roles and responsibilities

System Integrity

- Register products with system operator(s)

- Counting and reconciliation process

- Transparent and public reporting

Conclusion

Scientists estimate there is already more than 150 million tons of plastics in the ocean today19 and this is expected to triple by 2040 if no action is taken. The UN is rising to the challenge. In 2017 the UN Environment Assembly passed a resolution encouraging members to adopt “innovative” approaches to marine pollution, like container deposit systems.

After identifying the patterns between the world’s highest performing deposit systems, it’s clear there is a blueprint for success. By adopting a thoughtful approach – one based on the principles of Performance, Circularity, Convenience, System Management and System Integrity – the next generation of deposit systems can build on past learnings and take one step closer to a circular economy.

For more information on the 12 key elements of high-performing deposit return systems, click HERE to view and download the full Executive Summary in report form.

About TOMRA

We are living in an age of unprecedented consumption. This is pushing us beyond the boundaries of what our planet can sustain. TOMRA seeks to disrupt this paradigm with solutions that help to transform waste into resources. We believe TOMRA’s contributions of sensor-based technology, and over 50 years’ of experience working with private, public and civil sector stakeholders around the world, can help the entire value chain optimize resource productivity. To do this, TOMRA has invested primarily in two business areas:

TOMRA Collection

Founded in 1972, TOMRA provides reverse vending solutions for Clean Loop Recycling, collecting aluminum, plastic, and glass beverage containers to be continually reused and recycled back into new bottles and cans. With approximately 80,000 installations across more than 60 markets, TOMRA’s reverse vending machines capture over 40 billion used beverage containers every year toward a closed loop. This reduces reliance on raw materials and ensures fewer containers end up in our streets, oceans, and landfills. TOMRA’s reverse vending machines, digital solutions and service make recycling easy for the industry, system owners, retailers and consumers to contribute to a more sustainable planet.

TOMRA Recycling

TOMRA Recycling designs and manufactures sensor-based sorting technologies for the global recycling and waste management industry. Over 7,400 systems have been installed in more than 100 countries worldwide. Responsible for developing the world’s first high-capacity near infrared (NIR) sensor for waste sorting applications, TOMRA Recycling remains an industry pioneer with a dedication to extracting high purity fractions from waste streams that maximize both yield and profits. TOMRA Recycling and TOMRA Collection are owned by Norwegian company TOMRA Systems ASA, which is listed on the Oslo Stock Exchange. Founded in 1972, TOMRA Systems ASA has a turnover of around $1B and employs ~4,300 globally. For more information visit TOMRA.com.

CGLR’s business and sustainability network programming is supported by the Fred A. and Barbara M. Erb Family Foundation.